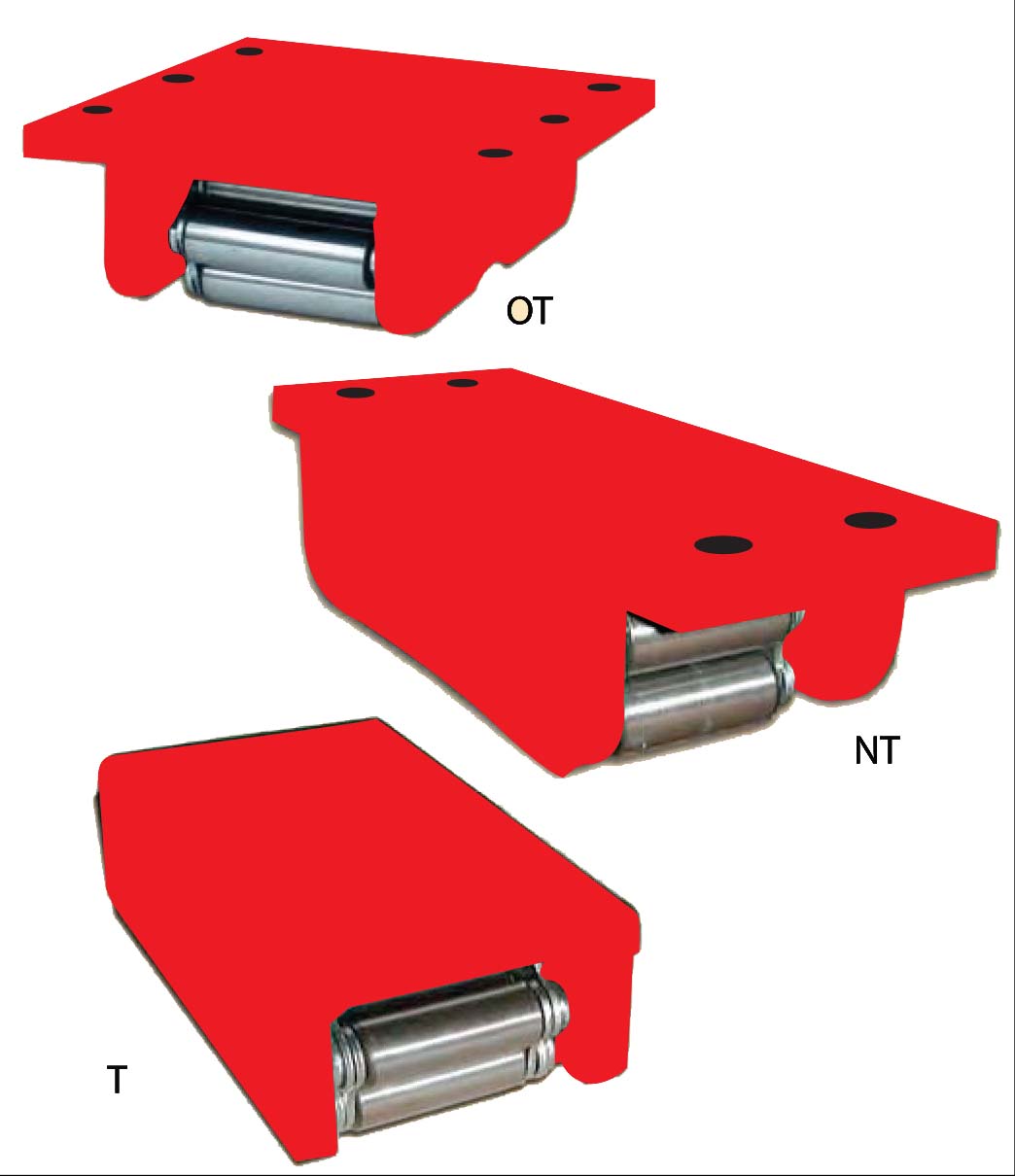

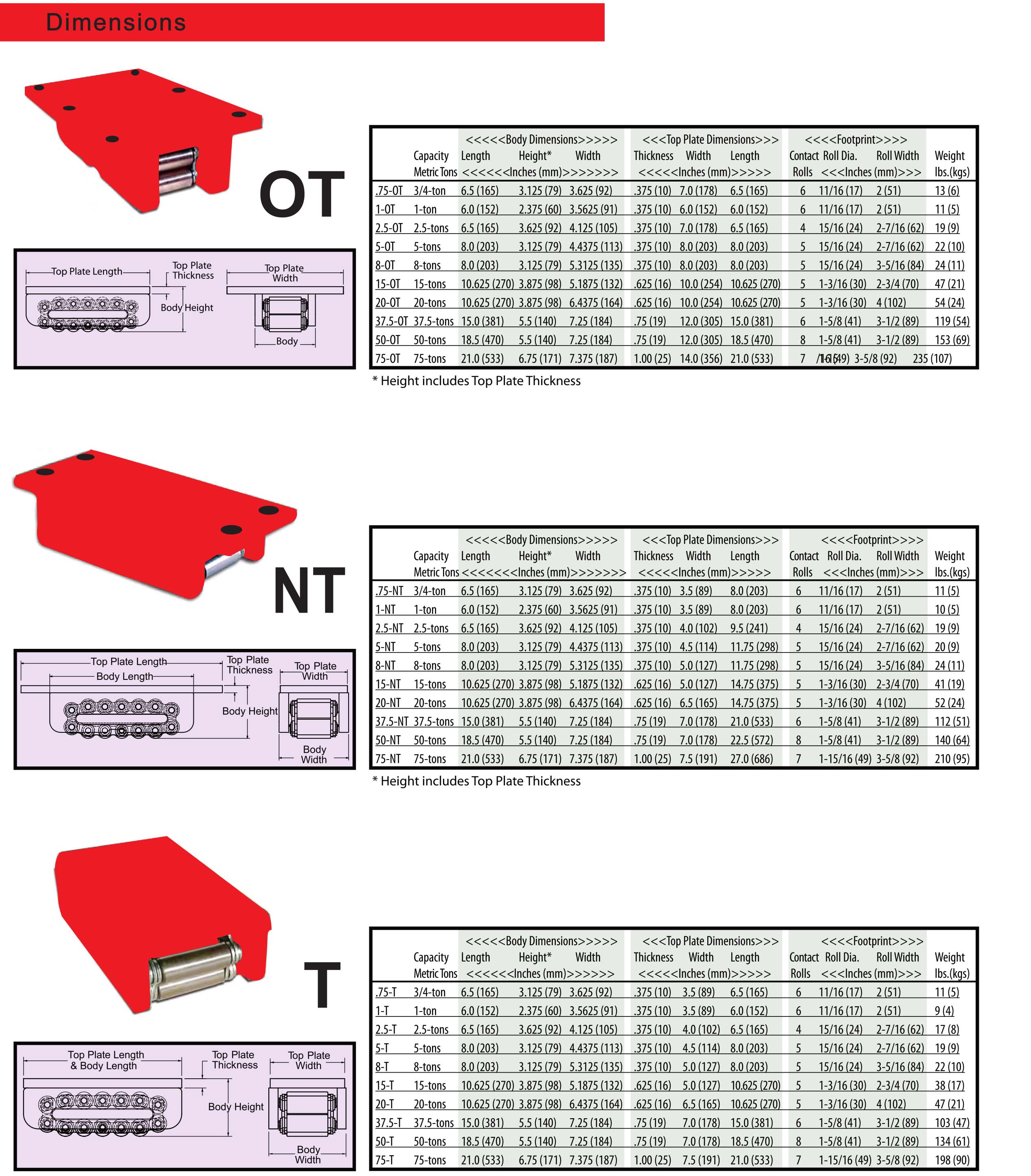

OT - T - NT Series Features

3S OT/NT/T Series Rollers offer a variety of top configurations. Selection is usually dependent upon the application. OT and NT style Rollers are bolt-on styles offered with standard hole patterns in oversized top plates. The hole patterns can be altered as needed or eliminated. T style Rollers have tops that are flush on all sides, ideal for weld or cavity mounting. Roller frames are fabricated from high-strength steel. Load plates of 37.5-ton and higher capacities undergo a special machine process to minimize side-to-side movement of chain.

Advantages

These rollers can withstand high static loading over long periods of time, often carrying the full load weight for more than a year with no adverse effects. Because loads are spread over a wide area and carried by the load plate and the contact rolls, rollers are ideal for many applications requiring the frequent movement of heavy loads. Rollers can also be used inverted, as static conveyors.

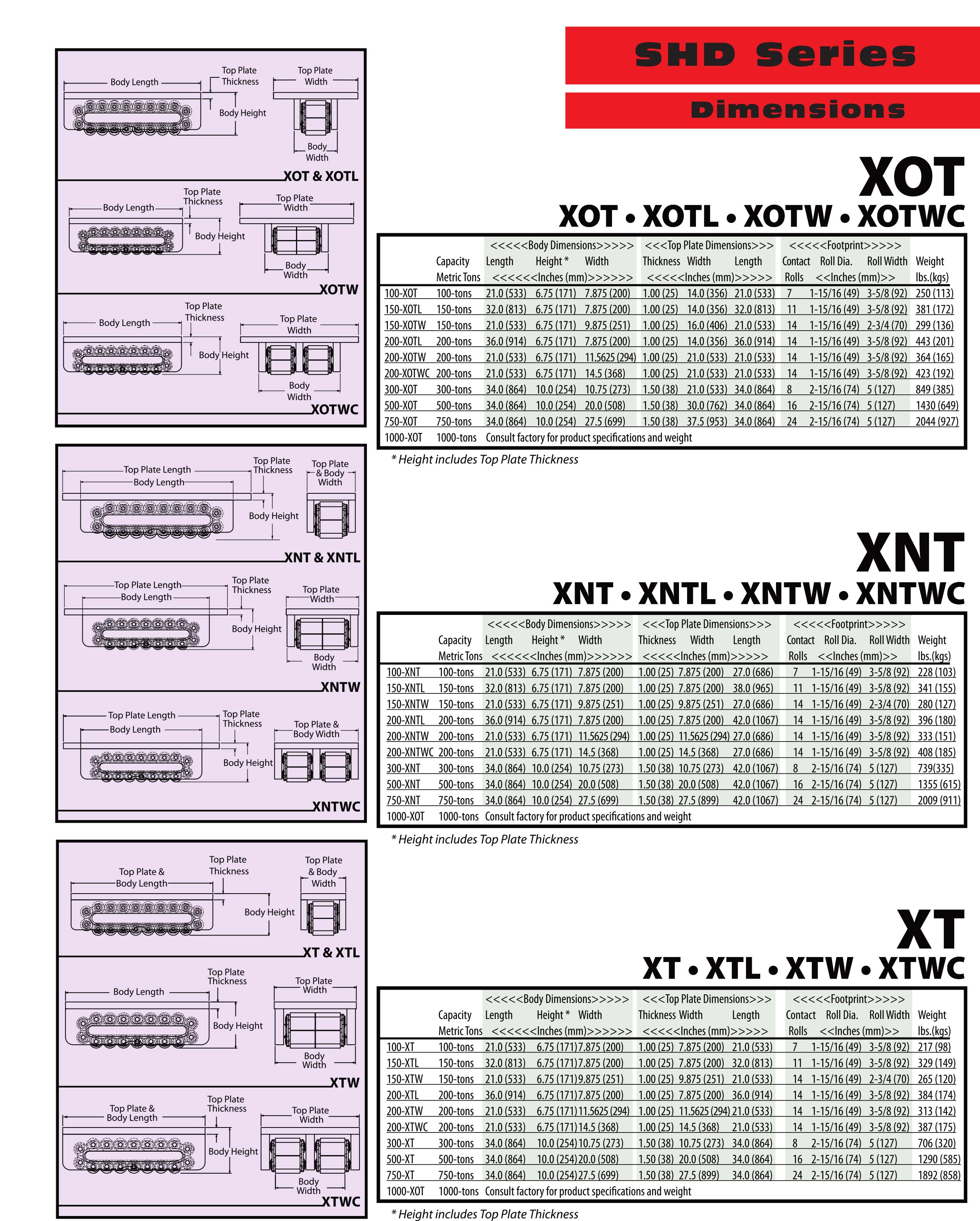

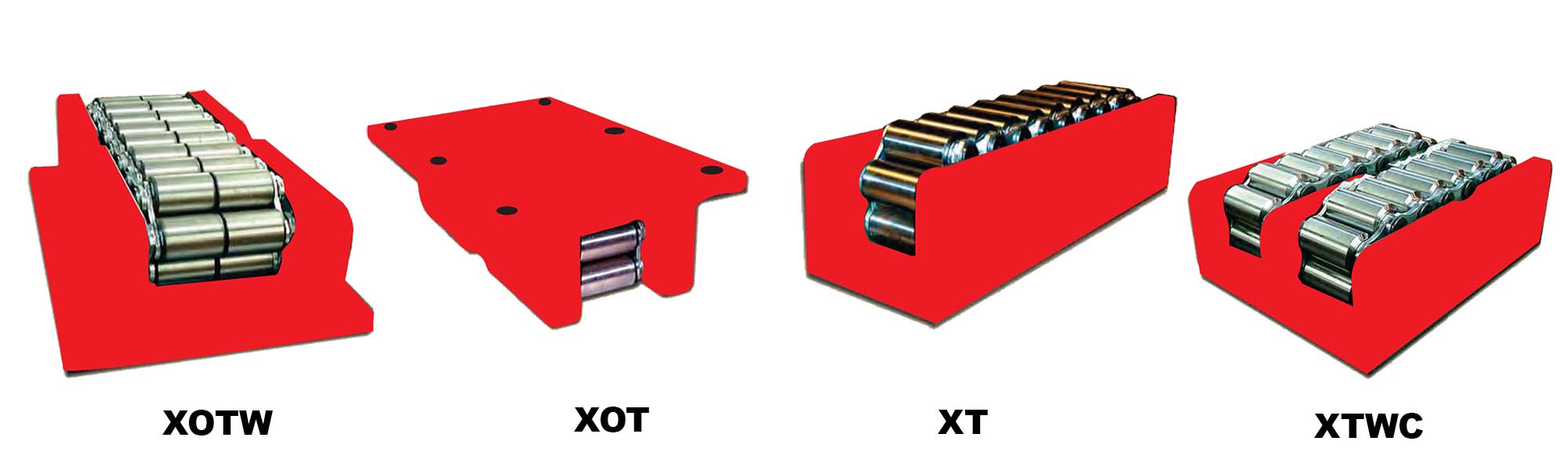

Super heavy Duty (SHD Series)

The Super Heavy Duty Series (SHD Series) 3S Rollers is an extension of the OT/NT/T Series, in that they follow the same design but have capacities from 100 to 1000 metric tons. There are several of these roller capacities available with the same overall height enabling users to mix sizes without the requirement of shims. Long and Wide versions of the 150-ton and 200-ton capacities are available, as well. Wide versions are offered with one complete (wide) chain or with two individual chains with a center plate dividing them. In this capacity range, there are many factors which may favor the selection of one model over another. For this reason, we encourage reviewing your application details with us. An Application Analysis form can be found on the back page of this brochure, as well as at our website.